From the Electrical Safety laboratory, we carry out the evaluation of the conformity of electrical and electronic equipment, from the point of view of electrical safety (Low Voltage Directive 2014/35/EU and international regulations).

To this end, it performs a wide variety of tests:

Electrical character tests. Tests are performed for insulation resistance, dielectric strength, leakage currents, distances in the air, leak lines and solid insulation, transverse and longitudinal strength, transient overvoltages, power and intensity.

Impact Protection Grades (IK) and Protection Grades (IP). These establish a classification system, which are used to calibrate their degree of protection.

Mechanical tests. These study the fall resistance, impact resistance, resistance of the wiring to tensile, compressive or torsional forces of the equipment.

Aging and endurance tests. This concerns accelerating aging to measure the durability of the material.

Warm-ups in normal and abnormal operation. Appliances are checked to rule out hot spots in them, as well as current peaks in their connection that increase the temperature of the equipment (overloads, short circuits, vacuum, etc.).

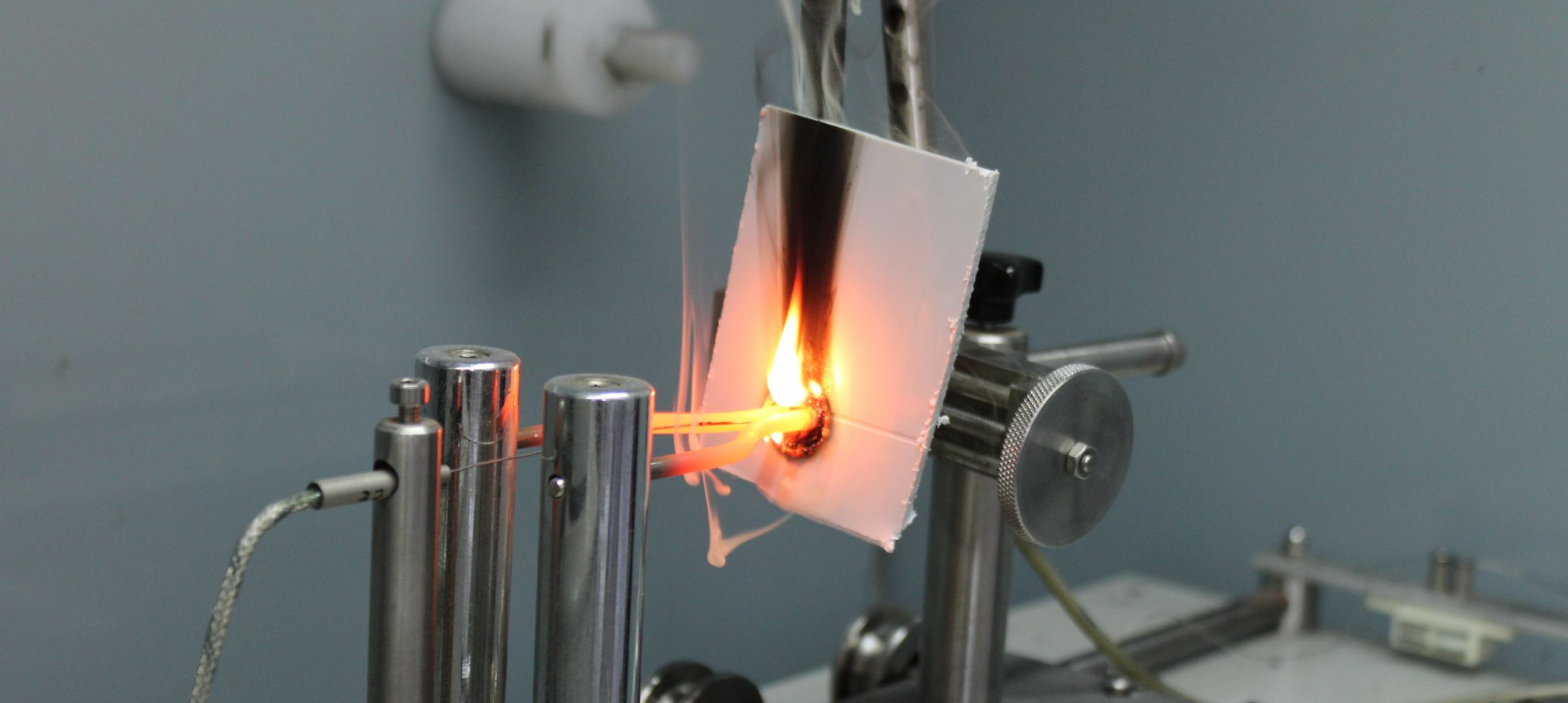

Short circuit test. They allow you to determine the most important parameters that define your behaviour.

These tests are accredited by ENAC, so that the product can be placed on the market in compliance with the legislation and the necessary guarantees for it to be safe. We help SMEs and large companies to develop designs, manufacture and market electrical and/or electronic products. During the design phase, product improvements will be studied to

implement and once the final product is available, the necessary tests for the certification of your product would be carried out using ITE laboratories.

Subscribe and don't miss out on all the latest news

Don’t miss anything in innovation and technology for companies, receive all our news.