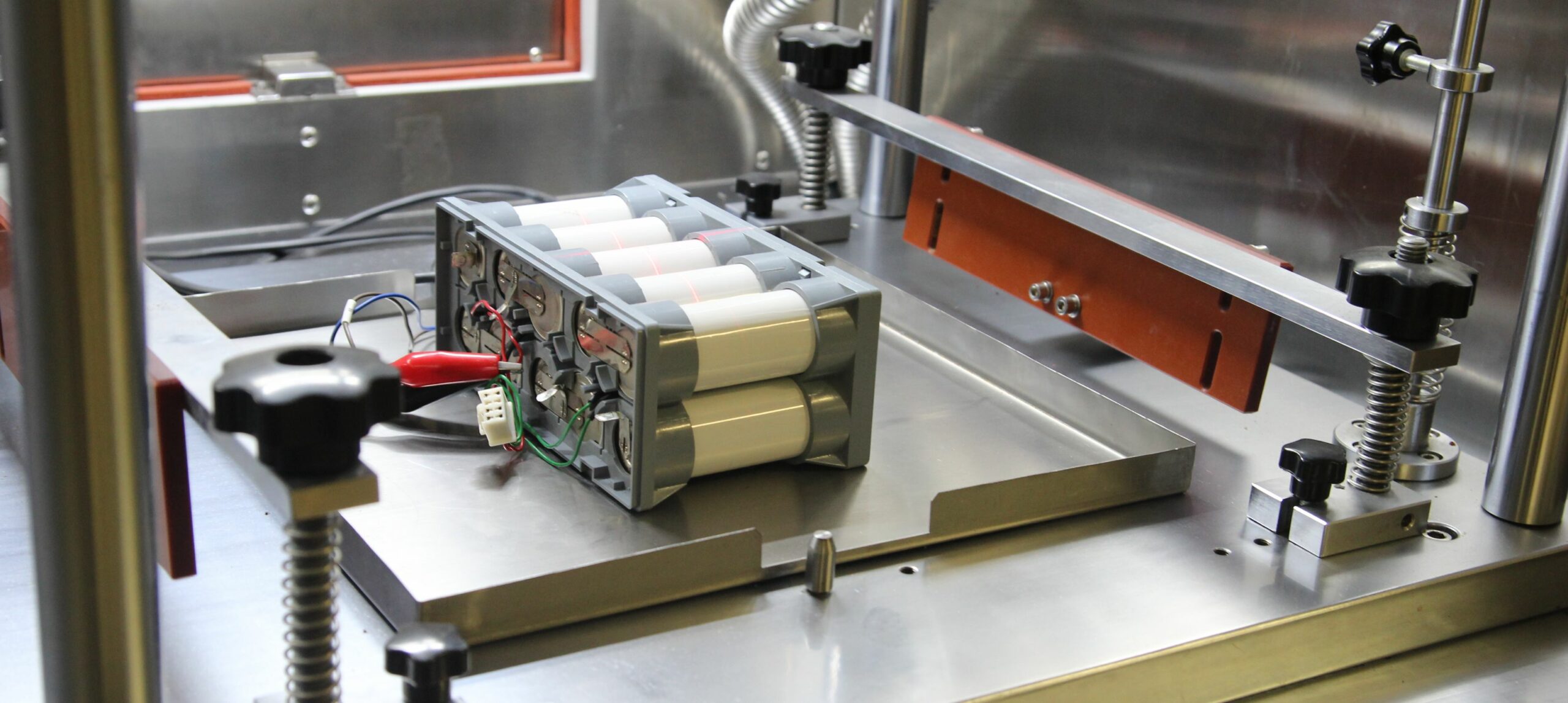

In order to guarantee the optimal storage of electrical energy, the battery testing laboratory has the appropriate equipment and qualified personnel with 30 years of experience, focused on the testing of lithium batteries from the cell to the pack level.

Semi-accelerated studies are carried out in order to test the evaluation of battery degradation and to investigate new models that allow greater energy efficiency. This is done through a combination of electrical and climate testing.

Battery safety tests are also carried out, using thermal and mechanical abuse equipment, to evaluate the response to conditions outside the range of use. In addition, it has the capacity to characterize batteries and carry out regulatory tests.

The aim is to provide innovative projects with the facility to validate models that simulate the electrochemical, electrical, thermal and mechanical behaviour of the battery. The combination of simulation tools and testing equipment allows to investigate improvements in the performance and safety of batteries (for cells, modules and packs) and their components, from pre-design stages to prototyping.

Our goal is to help companies, manufacturers and users of lithium batteries to cover all stages of the value chain, accelerating processes and reducing testing costs, allowing companies at any stage of the lithium battery market to be more competitive. In this way, thanks to the simulation tools available at ITE, you will be able to optimize pre-prototyping designs and testing equipment, product characterization and evaluation.