In the search for sustainable mobility and energy transition solutions, batteries emerge as a fundamental technology for the advancement of electric cars, renewable energy storage and reduction of carbon emissions. That’s why a new European project has just kicked-off, centered on the creation of a circular value chain for batteries, which promises to transform the life cycle of these products.

Led by INEGI – Institute of Science and Innovation in Mechanical and Industrial Engineering, the consortium is made up of 14 partners, who will look at the latter stages of batteries’ life cycle, with a special focus on the end of their useful life.

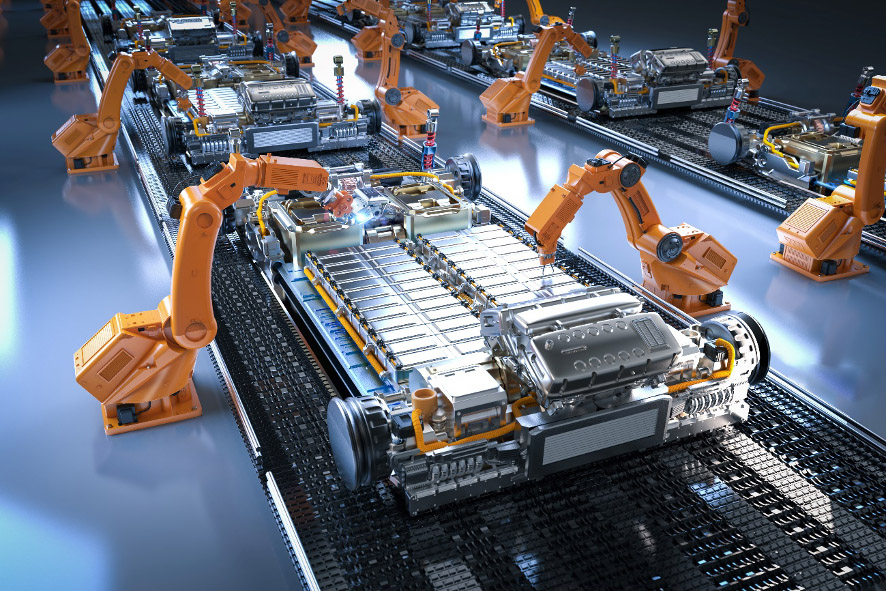

Used, defective and unstable batteries pose new challenges along the supply chain and require new industrial processes, automated equipment and tracking systems, as well as new strategies to prepare them for a second or third life, or even for the recycling of their components and materials. That’s why the consortium will work to overcome the technical and economic challenges involved.

After the reception of users’ defective and unstable end-of-life batteries, the project will develop 6 industrial processes: collection and sorting; safe and intelligent transport and storage into a battery remanufacturing plant; full diagnosis of packs, modules and cells; faster and safer battery discharge and energy recovery systems; automated disassembly of packs, modulesand cells; and pack reassembly for a second life.

These processes will be integrated and demonstrated in a real battery remanufacturing plant in Belgium. In parallel, the partners will draw standards for these industrial processes, design a traceability system along the value chain based on a battery passport, and evaluate sustainable circular business models.

ITE‘s main role is to lead WP4 in the implementation of battery diagnostics after disassembly of the pack into its modules, and in the design and development of the traceability system by means of a battery passport. It is also involved in the evaluation of cell-to-electrode disassembly techniques with a focus on improving recycling.

The project «REINFORCE – Standardised, Automated, Safe and Cost-Efficient Processing of End-of-Life Batteries for Second and Third Life Reuse and Recycling» is co-funded by the European Union through Horizon Europe, European Union’s framework program for research and innovation (R&I) for the 2021-2027 period. (https://reinforceproject.eu/)